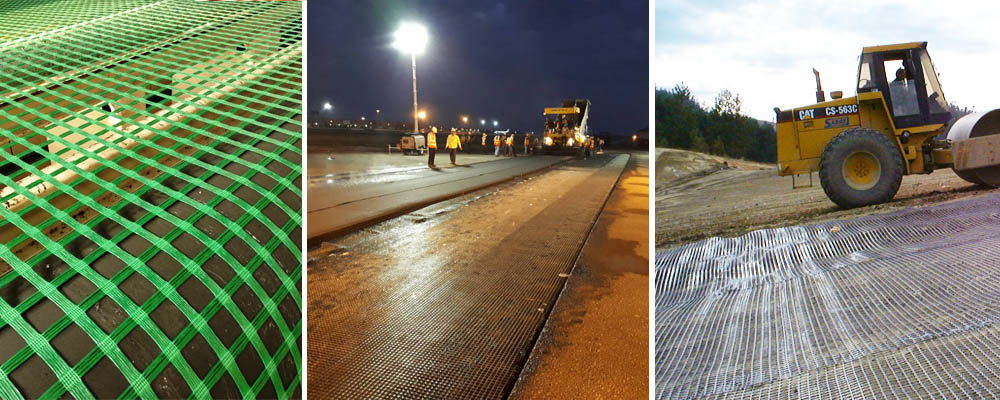

Geosynthetics Australia supplies commercial quantities of geogrids for soil reinforcement and road maintenance projects.

Soil reinforcement and road paving

Geogrids are engineered geosynthetic products made from polypropylene or polyester. Their open aperture confines substrates such as soil or gravel which increases the shear strength of the material. They are widely used in civil engineering and related applications for short and long term soil reinforcement and to stabilise embankments. They also provide tensile reinforcement for aggregate base courses in flexible or asphalt pavements.

Lateral spreading of base course aggregate or sub-base material is the most critical and common reason for failure in pavement structures. Polypropylene (PP) biaxial geogrids are manufactured by extruding high density polypropylene to form rigid arrays. Because the grids stabilize aggregates in the soil they increase its tensile strength and bearing and load support capacity. Additionally, when used in construction, aggregate thickness is reduced by up to 50%.

Composite geogrids consist of a biaxial grid and a nonwoven geotextile. The high tensile strength grid has a low elongation while the geotextile has high tear strength. Composite grids are suited for sites where both reinforcement of weak subgrades and separation and filtration is required. They are also used for waterproof protection.

High tensile woven polyester geogrids are made from high-strength, anti-embrittle, low shrinkage polyester yarn and sewn with high strength fibre filaments. They can be coated with PVC, SBR, Bitumen or Acrylic. The precision warp knitting offers superior junction strength and a high coefficient of soil interaction.

Glass fibre geogrids have a high tensile strength in both the longitudinal (MD) and transverse (CD) direction. They are a cost-efficient way to control reflective cracking in asphalt concrete overlays. They also dramatically extend the life of roads, airport runways and parking lots and save on maintenance costs.

Casizoid España analiza la integración de pagos por factura móvil

La industria del juego online en España atraviesa una transformación significativa en sus métodos de pago, donde la factura móvil emerge como una alternativa cada vez más relevante. Este sistema permite a los usuarios cargar sus depósitos directamente a la cuenta del teléfono móvil, eliminando la necesidad de compartir información bancaria o de tarjetas de crédito. Casizoid España ha llevado a cabo un análisis exhaustivo sobre cómo esta modalidad de pago está revolucionando la experiencia del jugador español, considerando tanto sus ventajas operativas como los desafíos regulatorios que presenta en el mercado nacional.

Evolución histórica de los métodos de pago en el sector del juego online español

Desde la regulación del mercado de juego online en España mediante la Ley 13/2011, los operadores han experimentado con diversos sistemas de pago para adaptarse a las preferencias de los usuarios. Durante la primera década de regulación, las tarjetas de crédito y débito dominaron el panorama, representando aproximadamente el 65% de todas las transacciones. Sin embargo, la llegada de las billeteras electrónicas como PayPal, Skrill y Neteller diversificó considerablemente las opciones disponibles entre 2015 y 2018.

El verdadero punto de inflexión llegó con la masificación de los smartphones y el desarrollo de tecnologías de pago móvil. Las operadoras telefónicas españolas comenzaron a ofrecer servicios de facturación directa que permitían micropagos para contenido digital, aplicaciones y servicios de entretenimiento. Esta infraestructura tecnológica sentó las bases para su posterior implementación en el sector del juego online, donde la inmediatez y la seguridad son factores críticos para la experiencia del usuario.

La Dirección General de Ordenación del Juego (DGOJ) ha mantenido una postura cautelosa pero abierta respecto a nuevos métodos de pago, estableciendo requisitos estrictos de verificación de identidad y prevención del blanqueo de capitales. Esta regulación ha influido directamente en cómo los operadores pueden implementar sistemas de pago por factura móvil, requiriendo procesos de validación robustos antes de activar esta funcionalidad para cada usuario.

Funcionamiento técnico y ventajas del pago por factura móvil

El sistema de pago por factura móvil opera mediante la integración entre el operador de juego online, el proveedor de servicios de pago y la operadora telefónica del usuario. Cuando un jugador selecciona esta opción, el cargo se añade automáticamente a su factura mensual de teléfono o se deduce del saldo de prepago disponible. Este proceso utiliza protocolos de autenticación que verifican la titularidad del número mediante códigos SMS o confirmaciones dentro de la aplicación de la operadora.

Una de las principales ventajas que Casizoid España identifica en su análisis es la reducción de barreras de entrada para nuevos usuarios. Muchos jugadores potenciales muestran reticencias a compartir datos bancarios en plataformas de juego, incluso cuando están debidamente reguladas. El pago por factura móvil elimina esta preocupación al no requerir información financiera sensible. Si deseas conoce más sobre las diferentes opciones de pago disponibles en el mercado español, resulta fundamental comprender que cada método presenta características específicas de seguridad y conveniencia adaptadas a distintos perfiles de usuario.

La inmediatez constituye otro factor diferencial importante. Mientras que las transferencias bancarias pueden tardar entre 24 y 48 horas en procesarse, y algunos métodos de pago electrónico requieren procesos de registro previos, la factura móvil permite depósitos instantáneos con mínima fricción. Esta característica resulta especialmente valorada por usuarios que desean realizar apuestas deportivas en eventos en directo, donde cada minuto cuenta.

Desde la perspectiva del control del gasto, este método ofrece ventajas significativas. Las operadoras telefónicas suelen establecer límites máximos de carga que oscilan entre 30 y 50 euros mensuales para servicios de entretenimiento, lo que actúa como mecanismo natural de juego responsable. Esta limitación inherente al sistema complementa las herramientas de autoexclusión y límites de depósito que los operadores están obligados a ofrecer según la normativa española.

Desafíos regulatorios y consideraciones de seguridad

La implementación del pago por factura móvil en el sector del juego online español enfrenta varios desafíos regulatorios específicos. La DGOJ exige que todos los métodos de pago permitan una trazabilidad completa de las transacciones y faciliten la verificación de la identidad del usuario. En el caso de la factura móvil, esto requiere que las operadoras telefónicas compartan información con los operadores de juego, planteando cuestiones sobre protección de datos personales conforme al Reglamento General de Protección de Datos europeo.

El proceso de verificación de edad representa otro aspecto crítico. Mientras que los contratos de telefonía móvil requieren mayoría de edad, existe la posibilidad de que menores utilicen dispositivos de adultos. Los operadores deben implementar sistemas adicionales de verificación que crucen el número de teléfono con bases de datos de identidad, añadiendo una capa extra de complejidad técnica al proceso.

La prevención del fraude constituye una preocupación constante. Los casos de suplantación de identidad o uso no autorizado de líneas telefónicas requieren protocolos de seguridad sofisticados. Casizoid España destaca en su análisis que los operadores líderes implementan sistemas de detección de patrones anómalos, como múltiples intentos de carga desde diferentes dispositivos o cambios súbitos en los hábitos de juego asociados a un número específico.

La reversibilidad de los pagos presenta particularidades en este método. A diferencia de las tarjetas de crédito, donde los usuarios pueden disputar cargos, las transacciones por factura móvil son generalmente definitivas una vez procesadas. Esto protege a los operadores contra fraudes de contracargo, pero también exige mayor responsabilidad en la implementación de confirmaciones claras antes de ejecutar cada transacción.

Perspectivas futuras y tendencias del mercado

El mercado español de juego online muestra señales claras de crecimiento en la adopción de pagos por factura móvil. Según datos del sector, aproximadamente el 12% de los nuevos usuarios registrados durante 2023 utilizaron este método para su primer depósito, una cifra que representa un incremento del 40% respecto al año anterior. Esta tendencia se alinea con el comportamiento general del consumidor español, que muestra preferencia creciente por soluciones de pago vinculadas al móvil en diversos sectores comerciales.

La evolución hacia el 5G y la mejora continua de las infraestructuras de telecomunicaciones facilitarán transacciones aún más rápidas y seguras. Las operadoras telefónicas españolas están desarrollando sistemas de autenticación biométrica integrados que podrían simplificar significativamente el proceso de verificación, reduciendo el tiempo necesario para completar un depósito a apenas unos segundos.

La integración con tecnologías emergentes como blockchain podría ofrecer nuevas posibilidades para mejorar la transparencia y trazabilidad de las transacciones. Algunos operadores internacionales ya experimentan con registros distribuidos que documentan cada movimiento de fondos, aunque su implementación en el mercado español dependerá de la evolución del marco regulatorio.

El análisis de Casizoid España sugiere que el futuro inmediato verá una consolidación de este método como opción estándar en la mayoría de plataformas reguladas. La clave del éxito residirá en equilibrar la conveniencia del usuario con los requisitos regulatorios de seguridad y juego responsable, un desafío que definirá la competitividad de los operadores en los próximos años.

La integración de pagos por factura móvil en el sector del juego online español representa una evolución natural hacia sistemas más accesibles y seguros. Aunque persisten desafíos regulatorios y técnicos, las ventajas en términos de conveniencia, seguridad de datos y control del gasto posicionan este método como una opción cada vez más relevante. El análisis realizado por Casizoid España evidencia que los operadores que logren implementar esta tecnología de manera eficiente, cumpliendo rigurosamente con la normativa vigente, estarán mejor posicionados para captar nuevos segmentos de usuarios y fidelizar a su base existente en un mercado cada vez más competitivo y tecnológicamente avanzado.