Geocomposite Cuspated Strip Filter Drains are easy to install, strong and a money-saving alternative to rigid drains for shotcreting, edge drains for roadways and landscape drainage applications.

40mm PVC Double Dimple Strip Filter Drain

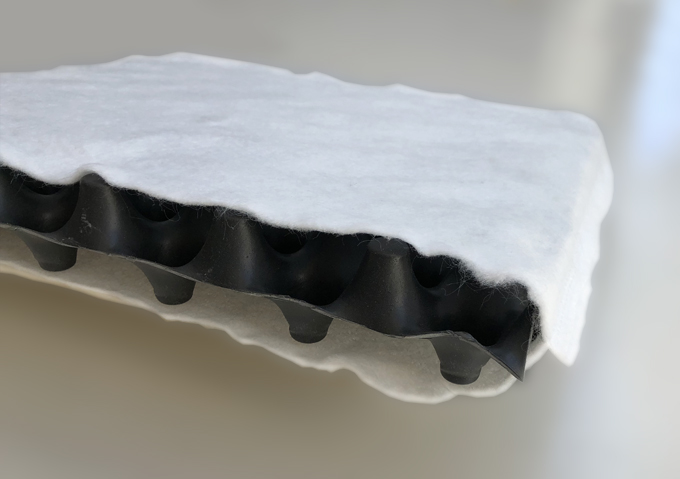

Filter Fabric Drain as supplied

Shotcrete Drainage

Reinforced shotcrete cladding is widely used to seal and stabilise the open face of walls, embankments and moderately weathered rock cuts with complex forms or shapes. It has high strength, durability and excellent bond strength.

Seepage can cause a build-up of hydrostatic forces behind a shotcrete wall and result in a catastrophic collapse of the surface. This can be caused by leaking utilities, a naturally high water table or unseasonal weather events.

Shotcrete failure caused by a build up in hydrostatic pressure

Strip Filter Drains, also known as prefabricated geocomposite drains are designed for sub-surface drainage behind shotcrete walls. They reduce hydrostatic pressure against a wall or slab and assist in maintaining the structural integrity of the wall from grade to footer. When properly installed, behind walls strip drains allows their design loads to be reduced by between 40% and 180%. Geocomposite drains are also easier to construct than aggregate drains on steep faces.

Strip Filter GeoDrains consist of a high compression strength, flexible HDPE or PVC core, wrapped in a strong nonwoven geotextile, that permits in-flow from both sides. The high-flow polyester nonwoven geotextile resists damage during installation, prevents fine particles from blocking the drainage core and intercepts a large volume of water under a low hydraulic gradient. The open pore space of cuspated strip drains is almost 20 times that of slotted drains and therefore require a smaller area to intercept the same quantity of seepage. Because water can drain away, hydrostatic pressure does not build up behind walls and the subgrade under pavements stays dry.

The flexible cuspated core allows for the efficient discharge of water. The core’s high compressive strength with minimal deflection under load, ensures good structural integrity during installation and service. The impermeable core also protects the shotcrete from water, with the added benefit of a surface-locking effect on the shotcrete when it is sprayed onto the strip drain.

Advantages of Cuspated Shotcrete GeoDrain

Geodrain’s cuspated core intersect significantly more seepage than slotted, rigid strip drains or perforated agricultural pipe. The open area of the cuspated core is approximately 65%. This is equivalent to 390cm2 per linear metre for a 300mm wide strip drain compared to 39cm2 for rigid slotted drains. As a result strip filter Geodrains collect up to 10 times more water over the same period of time. The gap between the geotextile and the core allows water to flow rapidly down the drain to the outlet tubes.

The 40mm x 300mm Geodrain has a higher in-plane flow rate than a similar sized Megaflo drain. Published data show Megaflo has an in-plane flow rate of 122 litres/minute at an hydraulic gradient of 1% compared to 150 litres/minute for a cuspated geocomposite drain. In addition, flexible geocomposite drains conform more closely to the contours of an embankment or rock face.

Because the permittivity and flow velocity of prefabricated geocomposite drains is standard for a particular hydraulic gradient, they eliminate errors in calculating the permeability caused by turbulent flow in open graded materials. Geocomposite drains that only permit in-flow from one side should be used directly against a concrete surface.

The geotextile fabric is fully compliant with the requirements of MRTS 27 Strength Class B – Filtration Class I & RMS R63 Strength Class B -Filtration Class I. The needle punched geotextile sock is sonically welded around the polymer core for added strength.

The core and geotextile are chemically compatibility with concrete.

Benefits of Cuspated Strip Filter Drains

- Hold reinforced shotcrete – Geotextile covered cuspated cores provide an excellent surface for the adhesion of shotcrete and other construction materials.

- Dimples reduce shotcrete rebound by 10-20% and save money because less shotcrete is lost during spraying.

- Easy to store, transport and install – Lightweight strip drain is placed easily and quickly. No heavy equipment or skilled labour is required.

- High flow capacity provides faster hydrostatic relief – The open area of the cuspated core collects up to 10 times more water than rigid strip drains. The cuspated core provides multiple channels for vertical and horizontal water flow, thereby lowering the water table behind the shotcrete surface. In addition, the filter fabric permits a high volume of water into core, while restraining soil particles.

- Outstanding durability – The polymer core’s high crush strength resists high loads from in-fill and formwork. Both core and fabric are unaffected by fungi or bacteria and resist acids and alkalis normally found in the soil.

- Sustainable – Geocomposite drains have a high recycled content, increase water efficiency, manage storm-water runoff and help effectively manage site issues. Geocomposite drains help to conserve aggregate resources.

- Predictable performance – Uniform properties and quality product testing deliver reliable performance.

GeoDrain Applications

There are many different types of slope/embankment stabilization and drainage applications based on project-specific requirements and conditions.

GeoDrain options for shoring walls include:

- Full wall coverage using sheet drains

- Partial wall coverage using chimney drains

- Weep hole outlets at each sheet/chimney at the wall base; lateral drainage using geocomposite strip drains

- Perforated pipe at the wall base

Cuspated strip drains prior to shotcreting an embankment

Cuspated “chimney drains” are widely used for pressure relief behind reinforced soil walls and slopes including:

- Building foundations and basements

- Bridge abutments

- Road tunnel linings (especially on rock faces)

- Retaining walls

- Drainage behind facings to bored pile and diaphragm walls

- Runoff from footpaths, cycleways and verges

“Chimney drains” may also be used in select applications where full wall coverage is not required, or is not cost effective. Flexible cuspated filter strip drains collect more water and fit closer to the wall surface than rigid drains.

GeoDrain Installation

Filter Strip Drains are installed vertically in applications where full wall coverage is not practical due to protrusions in the wall surface, such as soil nails.

The flexible strip drain is placed firmly against the shoring surface (soil/lagging/shotcrete/soil nailing/etc.). The spacing of the “chimney drains” depends on factors such as the width of the strip drain, the hydrostatic pressure and shotcrete coverage, and will be determined by an hydraulic engineer.

To ensure good contact with the soil or rock face, the flexible strip drain is secured by pins driven through the drainage strip and into the ground behind.

Standard and specialised connectors and outlets transition the collected water from the strip drain to round, smooth wall, PVC or corrugated HDPE pipe. It is essential that outlet fittings and pipes are not crushed and kept free from debris.

Specifications

| Core Properties | Test Standard | Units | Value | ||

|---|---|---|---|---|---|

| Thickness @ 4mm deflection | ASTM-1777 | mm | 18 | 25 | 40 |

| Flow capacity i=1.0 |

ASTM 4716 | l/min/m | 110 | 150 | |

| Compressive Strength | ASTM 1621 | kPa | 270 | 225 | 200 |

| Polymer | HDPE | PVC | |||

| Core profile | Cuspated on both sides | ||||

| Thickness @ 4mm deflection | ASTM-1777 | mm | 40 | ||

| Roll Length | m | 50m | |||

| Roll Width | mm | 100/200/300/450 | |||

Pavement Edge GeoDrain

Subsurface drainage is essential to maintaining the design service life of roads. Pavement Edge Drains, also known as fin drains, were introduced during the mid 1980s to collect and remove water within and under the pavement structure.

When properly designed and installed, geocomposite drains reduce stripping in AC Pavements, reduce pumping at the joints of PCC Pavements and remove water from the subgrade. This increases the strength of the subgrade and the life of the pavement. Research has shown that properly installed pavement edge drains extend pavement life by an average of seven years.

Pavement Edge GeoDrain consists of an high compression strength, polymer core, wrapped in a strong nonwoven geotextile that permits in-flow from both sides. The high-flow polyester nonwoven geotextile filter prevents fine particles from blocking the drainage core and allows water to freely drain away. This ensures a high in-plane flow rate for the efficient discharge of water. PVC cored edge drains are creep resistant and have a high compressive strength with minimal deflection under load, thereby maintaining good structural integrity during installation and service.

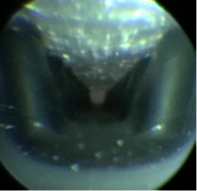

Water flow in a cuspated panel edge drain under load monitored by an endoscope

Advantages of GA Pavement Edge Drain

Geocomposite edge drains are more efficient at drainage than aggregates. The double cuspated core intersects up to 10 times more water than slotted, rigid strip drains and 20 times more than perforated agricultural pipe. The open area of the cuspated core is approximately 65% or 390cm2 per linear metre for a 300mm wide strip drain. By comparison, the open area of the same size rigid strip drain is only 39cm2.

The 40mm x 300mm Pavement Edge GeoDrain also has a higher in-plane flow rate than a similar sized Megaflo drain.

Benefits of Pavement Edge GeoDrain

The open area of the cuspated core collects up to 10 times more water than rigid strip drains. The cuspated core provides multiple channels for vertical and horizontal water flow along the trench and the filter fabric permits high rates of water transmission into the core while restraining soil particles.

Low installation and material costs save time and money. The combined installation and material cost is up to half that for aggregate drains. The narrow width reduces excavation costs and cover requirements and can greatly reduce vehicle movements during construction.

Pavement Edge GeoDrain is lightweight, easy-to-handle and quick to install. No heavy equipment or skilled labour is required and the ends connect easily to each other.

GA PVC filter strip drain is more resistant to creep and thermal ratcheting under compressive loads than HDPE drains.

Pavement Edge GeoDrain has outstanding durability. The 200pKa crush strength core resists damage during installation and at greater soil depths. The high tear and puncture strength of the thermally bonded fabric insures no damage during backfilling or use.

Pavement Edge GeoDrain is unaffected by fungi or bacteria and resists acids and alkalis normally found in the soil.

The uniform properties, rigorous testing and quality materials deliver predictable drain performance and road maintenance costs.

Applications for Pavement Edge GeoDrain

Pavement Edge GeoDrain is ideal for a wide range of applications where ground water needs to be intercepted, collected and discharged. These include:

- Pavement edge drains for subsurface drainage along roadway edges.

- Horizontal drainage at sporting venues including golf green and fairway drainage; sports fields and stadium.

- Removing standing water in landscape drainage applications such synthetic turf, natural turf, playgrounds and gardens.

- Waste management drainage for landfills

Installation of Pavement Edge GeoDrain

Excavate the trench to the desired width and depth using a standard trenching machine. Make sure to allow sufficient cover (usually 300mm) from the surface to the top of the panel.

Place the panel drain at the bottom of the trench and hard against the side of the trench to drain the infiltrated water. Where site conditions result from seepage entering from both sides of the trench, the drain should be located in the centre.

To ensure the pavement edge drain is firmly against the trench wall, temporarily support it while backfilling. Backfill the trench with well graded clean well washed sand or fine gravel to avoid deforming the core or tearing the geotextile. The sand helps to filter out fines and prevents them clogging the filter fabric. Compact the sand by vibrating or tamping with a mechanical tamper or wash in the sand drainage material and then compact. Increasing the density of the sand, increases the performance of the drain.

Pavement Edge GeoDrains join together with a purpose made coupler. The geotextile must fully cover all of the exposed core to prevent soil particles entering and blocking the cuspated core.

Outlet connections transition the collected water from the Pavement Edge GeoDrain to a 100mm diameter smooth wall, PVC or corrugated polyethylene pipe. It is essential that outlet fittings and pipes are not crushed and kept free from debris.

Specifications – Strip Filter Drain

PVC Pavement Edge GeoDrain is supplied in 50m long rolls. Standard sizes are 40mm high and 200mm, 300mm and 450mm wide.

| Core Properties | Test Standard | Units | Value |

|---|---|---|---|

| Flow capacity i=1.0 |

ASTM 4716 | l/min/m | 150 |

| Compressive Strength | ASTM 1621 | kPa | >200 |

| Polymer | PVC | ||

| Core profile | Cuspated on both sides | ||

| Thickness @ 4mm deflection | ASTM-1777 | mm | 40 |

| Minimum Stiffness (RMS 3556) | >11.0 for width 200- 400mm | ||

| Roll Width | mm | 100/200/300 | |

| Roll Length | m | 50m | |