High strength, reinforced stitched non-woven geotextiles are both lightweight and exceptionally strong. They are custom manufactured from polyester and polypropylene fabrics to meet special requirements such as stabilising coastal areas. These reinforced stitched non-woven geotextiles are very cost competitive and offer superior resistance to attacks by vandals.

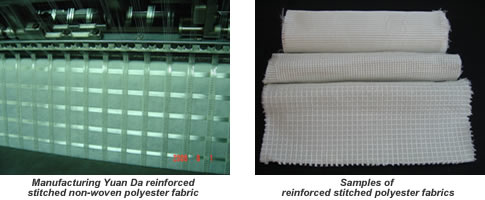

Reinforced Stitched Non-woven Polyester Geotextile

Manufacturing high strength nonwoven geotextiles involves using specialist looms to knit a complex network of high tenacity multifilament polyester yarns into a nonwoven fabric. The stitching creates a composite geotextile with both woven and nonwoven properties.

Heavy Duty Liner Underlay

Polyester Reinforced Non Woven Underlay

Our heavy-duty, high puncture strength reinforced stitched non-woven underlay consists of two layers of non-woven polyester fabric, needle-punched to an inner layer of reinforced stitch bonded polyester fibres. When used as a non-woven liner underlay it provides superior protection for liners from abrasion. It also prevents long term damage caused by indentation from stony soils under high static loads. Traditionally, subgrades had to be well compacted and offer an even grade, free from sticks, stones and protrusions to prevent any damage to a geomembrane.

This heavy duty reinforced stitched non-woven geotextile is an ideal underlay for stormwater outfalls, marine scour pads, pond and dam liners, woodchip underlay pads and separation layers. It also delivers improved performance when welding HDPE liners on undulating surfaces.

| Property | Unit | 408 Grade | No. 1 | No 4 | No. 5 |

|---|---|---|---|---|---|

| Fabric Weight | g/m2 | 408 | 1175 | 810 | 565 |

| Thickness | mm | 2.0 | 2.9 | 2.5 | 2.0 |

| Tensile Strength (longitude) | kN/m | 70 | 235 | 150 | 81.4 |

| Grab Elongation (longitude) | % | 13.3 | 15.2 | 14.8 | 14.6 |

| Tensile Strength (latitude) | kN/m | 105 | 220 | 155 | 87 |

| Grab Elongation (latitude) | % | 13.4 | 15.8 | 15.1 | 14.4 |

| Tear Strength (longitude) | N | 950 | 3240 | 2150 | 1250 |

| Tear Strength (latitude) | N | 900 | 3350 | 2480 | 1320 |

| CBR Strength | N | 6210 | 14500 | 9560 | 6550 |

| Permeability K20 | cm/s | 0.403 | 0.05 | 0.05 | 0.05 |

| Equivalent Aperture O95 | mm | 0.2 | 0.1 | 0.1 | 0.1 |

| Roll Width | m | 5.3 | 5.3 | 5.3 | 5.3 |

| Roll Length | m | 100 | 100 | 100 | 100 |