Laying glass geogrid to prevent pavement cracking on an airport runway

Glass geogrids are a high strength self-adhesive reinforcement biaxial geogrid designed to control reflective cracking in asphalt concrete overlays on roads, freeways, bridges and car parks. They significantly extend the useful life of pavements, airport runways and parking lots, and reduce maintenance and life-cycle costs. Pavement reinforcement geogrids withstand high and low temperatures, resist corrosion and are not affected by creep.

Reinforcing the roadway pavement with glass fibre geogrids provide asphalt with a much greater ability to resist tensile stresses that cause longitudinal and random cracking in the pavement. Glass paving reinforcement grids transfer stress in asphalt overlays thereby reducing both thermal and stress-related cracking. This allows the cyclic loading of vehicles to disperse throughout the pavement and lower reflective cracking through a new asphalt overlay by up to 300%.

Unlike simple mill and fill maintenance options pavements treated with fibreglass geogrid remain essentially crack free. They are also a cheaper option and do not require long lane closures for full depth reconstruction.

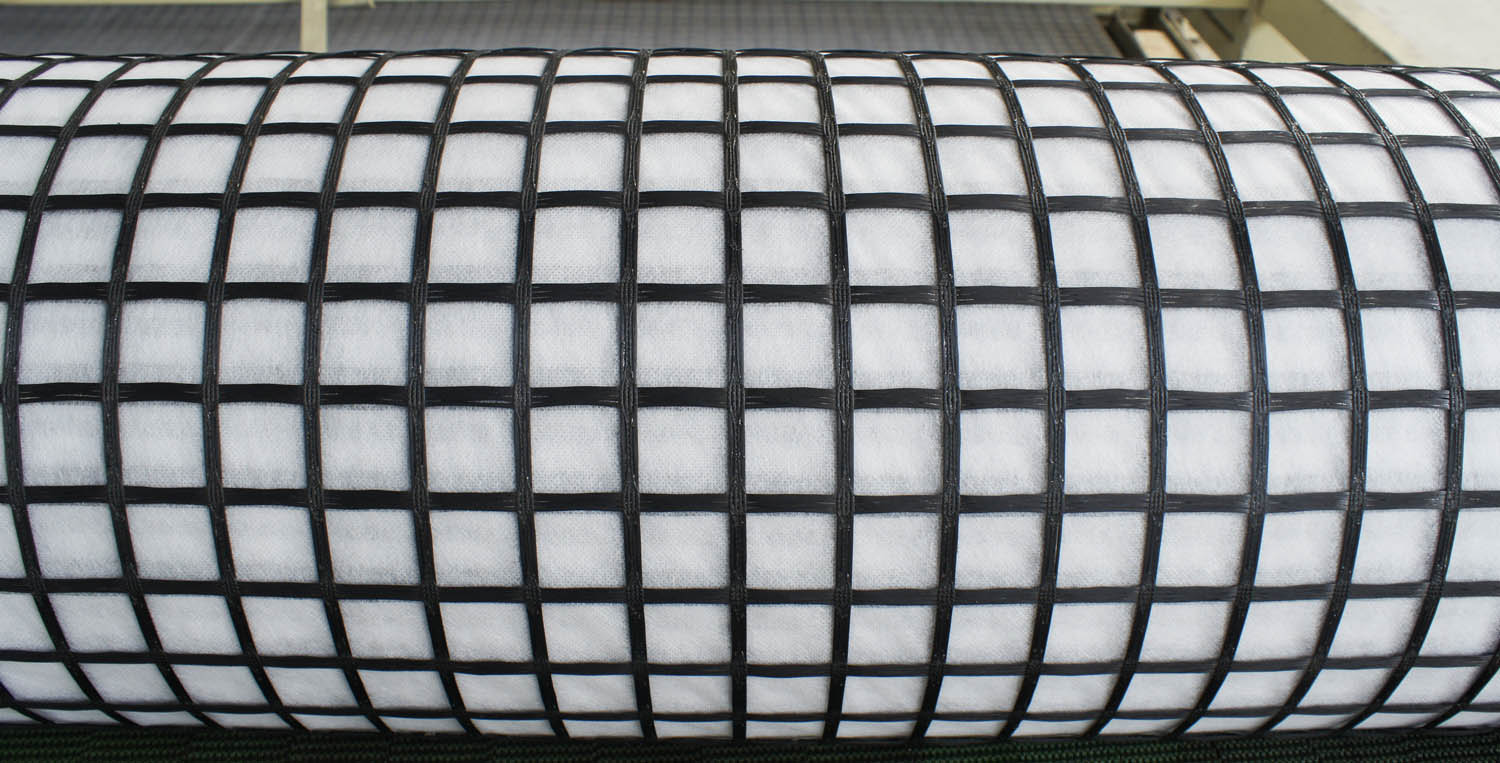

Lane width, high modulus glass fibre composite geogrid with self adhesive backing

Our glass geogrids are manufactured to international standards from woven fibreglass strands, coated with bitumen and a self adhesive layer. Each strand has a remarkably high tensile strength and high modulus of elasticity. This is particularly important as asphalt concrete typically cracks at low strains. The silica based geogrids are manufactured to ISO 9001 quality standards and have a high melting point (+215 degrees C). They meet the requirements of Queensland Transport and Main Roads Specification MRTS104.

Glass paving geogrids have low elongation and bond well on the levelling course. The fiberglass grid is “sandwiched” between the levelling and surface courses of asphalt. This turns crack stresses horizontally and dissipates the stress. The self-adhesive backing allows for quick installation. Glass geogrids not only decrease the cost of construction but also prolong the service life of the pavement.

Glass geogrids are easily milled, and environmentally friendly. They are available in full lane width rolls (from 1.5m to 6.0m).

Glass Grid Highlights

- Reduce reflective cracking caused by different rates of contraction

- Bituminous coating enhances pavement life

- Prevent cracks along joints caused by uneven sedimentation

- Self-adhesive surface reduces installation time

Glass Grid Applications

- Resurfacing and repair of existing asphalt roads

- Reinforcement of asphalt pavements

- Sealing road widening joints

- Construction of new roads