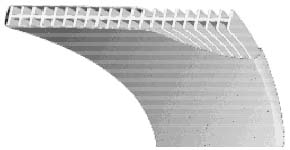

Wick drains, also known as Prefabricated Vertical Drains (PVD), significantly increase the speed of consolidation of deep, soft, clayey soils. This improves the strength and stiffness of the soil strata before construction begins and virtually eliminates uneven post-construction settlement. Dual core wick drains consist of an extruded polypropylene core to allow maximum water flow and a high quality non-woven geotextile filter bonded to both sides to maintain effective filtration.

The dual core integrated structure withstands installation stresses and offers improved filtration and drainage.

Applications

Integrated wick drains outperform traditional wick drains made from separate cores and geotextile filter socks. They are used throughout Asia to consolidate soil on industrial and commercial development projects, including tailing ponds and leach pads.

Installation

Wick drains are inserted vertically into the soil through a hollow mandrel mounted on an excavator or crane mast. At the bottom of the mandrel the PVDs are connected to an expendable anchor plate. A vibratory hammer or static method forces the mandrel to the design depth. The mandrel is then removed, leaving the wick drain in place.

A triangular pattern of installed vertical wick drains provides short drainage paths for ground water. Ground water under pressure passes through the filter fabric into the core where it flows up the drain and out of the soil. The water only has to travel to the nearest drain to reach a free drainage path. This accelerates the consolidation process and the construction schedule. The speed of consolidation can be increased by laying heavy concrete or other blocks on the above ground surface.

| Item | Unit | Type A | Type B | Type C | Test Method | |

|---|---|---|---|---|---|---|

| Dual Drain Core | PE/white | |||||

| Bonded geotextile filter | PET/white | |||||

| Width | mm | 98+/-1 | 98+/-1 | 98+/-1 | ASTM D3774 | |

| Thickness | mm | >4.0 | >4.5 | >5.0 | ASTM D5199 | |

| Tensile Strength(Dry state) | KN/Core width | >=2.0 | >=2.4 | >=2.8 | ||

| Lengthways Discharge Capacity @ 350 kPa | cm3/s | >=60 | >=70 | >=80 | ASTM D4716 | |

| Lengthways Discharge Capacity @ 350kPa(buckled) | cm3/s | >=40 | >=50 | >=60 | ||

| Transverse Discharge Capacity | l/s | >=1×10-1 | ||||

| Tear Strength (Lengthways) | N | >=70 | >=70 | >=70 | ASTM D638 | |

| Puncture Strength | N | >=400 | >=400 | >=400 | ||

| Composite repellence break | N/M | No Rupture, No Peel off | ||||

| Filter Fabric | Weight | g/m2 | 105~120 | >=105~120 | 105~120 | |

| Thickness | mm | 0.28~0.32 | ||||

| Lengthways tensile strength(dry state) | N/cm | >=25 | >=30 | >=30 | ASTM D638 | |

| Transverse tensile strength(wet state) | N/cm | >=25 | >=25 | >=25 | ASTM D638 | |

| Filter permittivity | cm/s | >=5.0×10-3 | At water 24hours | |||

| Apparent Opening Size | mm | <=0.10 | ||||

| Roll Width | mm | 98 | ||||

| Roll Weight | kg | 30 | ||||