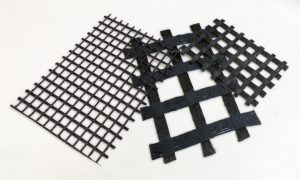

Polyester (PET) Woven Geogrids are used for soft and hard rock mining, environmental engineering, roads and pavements, earthworks and foundations where extremely high tensile strength with low elongation is required.

High tensile geogrids are manufactured from high-modulus and high strength long polyester fibres which are warp-knitted, bundled together and coated with PVC, Bitumen, SBR or acrylic acid. Woven geogrids are preferred for a range of soil reinforcement applications, including slopes and retaining walls.

High tensile geogrid for soft and hard rock mining applications

Our high strength geogrids range from 20kN to 1200kN/m at strains of less than 10%. PET geogrids can also be manufactured in a range of aperture sizes to suit specific applications. They are a good substitute for traditional metal mesh, plastic mesh, steel-plastic mesh and other materials.

Installing Geogrid in an underground coal mine

Woven Geogrids are coated with a flame retardant and/or anti-static treatment.

PET Rockface Geogrid

Our new woven rock face geogrid is made from high strength polyester fibres coated with a special PVC emulsion to make it stiffer and resistant to blasts. Unlike steel mesh, polymer geogrids do not damage rock crushers and are significantly cheaper and safer.

Features of Polyester Geogrids:

- High tensile strength and low elongation

- Excellent creep resistance

- High junction node strength

- UV resistant

- Corrosion resistant, chemically and biologically inert

- Flexible and durable

- Safe and easy to install

- Resist installation damage

- Cost effective

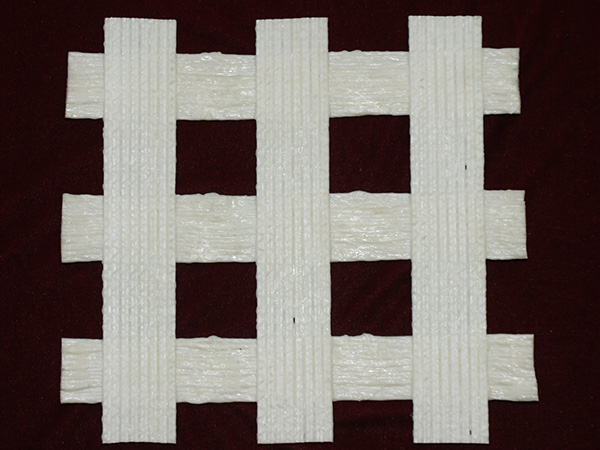

PVC coated woven polyester geogrid

High tensile polyester geogrids

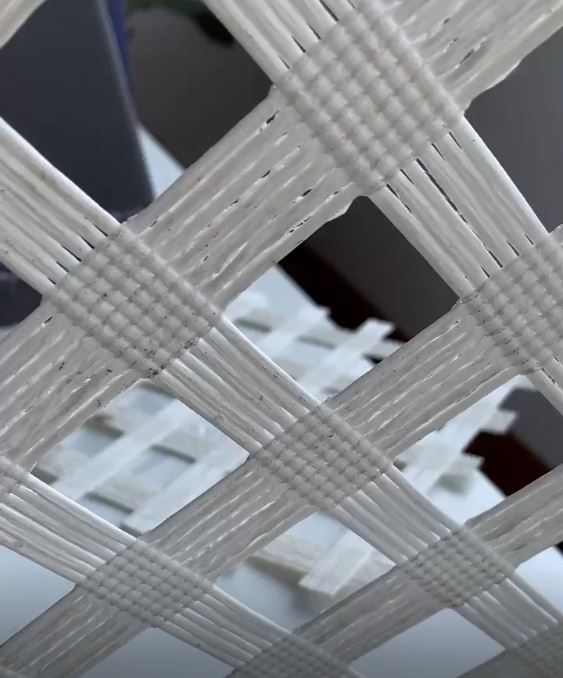

Woven geogrid coating line

PVC coating line

Geogrid Weaving Loom

Geogrid Weaving Loom

Woven Geogrid Applications:

- Soft and hard rock mining – long wall shield recovery screens, mine roof and rib control, reinforced highwalls, temporary and permanent tunnel support, heap leach and tailings

- Soil stabilisation

- Subgrade improvement

- Piled foundations

- Bridging voids and sinkholes in landfills

- Reinforced earth structures on poor foundations

- Road stabilisation, railways and pavement construction

Note: These geogrids are not recommended for use as a road base, or other applications that require fill greater than 40mm deep.

Quality assurance testing