Installing perforated geocells for road stabilisation

GA Geocells are made of lightweight, flexible, three-dimensional, expandable panels engineered from Ecoloy HDPE for greater chemical and physical performance. Cellular Confinement Systems are a cost-effective way to stabilise soil, construct retaining walls and ensure long term erosion control.

An extensive quality control program and the latest technology ensures that GA Geocells are manufactured to the highest international standards and ultrasonically welded for maximum performance.

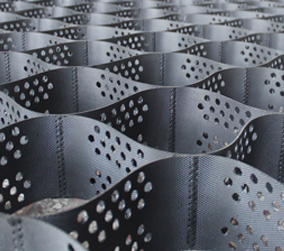

Perforated Geocells

Multi-layered geocells are an ideal solution for gravity and MSE Retaining Walls

When infilled with compacted soil, concrete, sand or gravel, geocells stabilise soils by preventing the lateral movement of particles. As pressure is applied to the soil, the tensile stress on the cell wall increases. The walls of the geocell are textured to increase soil‐geocell wall friction and to prevent the matrix lifting from the ground if installed with a concave profile. The depth of the cells, size of each cellular unit and whether or not the sides are perforated depends on the design requirements. Perforated cell walls are recommended when the Cellular Confinement System is to be grassed on slopes steeper than 10%. This allows the lateral movement of air and water through the structure, prevents water logging and for the infill to retain its strength. Multi-layered geocells fulfill all structural design requirements for both gravity and Mechanical Stabilised Earth (MSE) Retaining Walls.

GA Geocell Applications

Cellular Confinement Systems are widely used for erosion control and slope protection, load support, ground stabilisation, gravity retaining walls, MSE retaining walls and protecting channels from erosion. A soil slope reinforced with geocells creates a solid base that distributes the load over a wider area, reduces settlement of soft soil, improves shear resistance and load carrying capacity, and reduces distortion. GA Geocells help vegetation to establish and create surfaces that are easily maintained.

Installing geocells for slope stabilisation

GA Geocells can be used with many types of temporary and permanent pavements, including porous asphalt and porous block paving. They can be used to protect the root structure of trees from damage caused by the compaction due to vehicular traffic. The porous surface ensures that water and essential nutrients reach the tree roots. By laying a non-woven geotextile under the geocell fines cannot wash through and clog the system.

Cellular confinement systems can be used as an alternative to Rip Rap rock armouring where suitable large rock is not available. However, in areas of high flow velocity, geocells filled with small rocks are generally not a suitable replacement and concrete mats should be used.

- Erosion control

- Load support – hard pads for heavy equipment, road and rail support

- Slope protection

- Channel protection

- MSE Retaining walls

- Ground stabilisation and temporary haul roads

- Tree root protection

GA Geocell Installation

Stabilising a road base with geocells

To minimize transport costs, geocell panels are folded flat and stored on pallets. During installation the panels are expanded to form cells. The sections are filled with material such as soil, sand, aggregate or recycled concrete, and then mechanically compacted to ensure that the fill is flush or slightly below the adjacent terrain. Where it is important to separate a clay substrate from a gravel fill, a non-woven geotextile can be laid beneath the geocell.

Easy to install geocell panels using tendons, anchors and clips

Specifications

Ecoloy HDPE geocells are available in a range of colours and depth and cell openings with or without perforated walls.

| Product | Expanded Cell Size (width x length) mm |

Expanded Panel Size (width x length) m |

Expanded Panel Area m2 |

|---|---|---|---|

| INFRACELL75-356 | 259 x 224 | 2.59 x 7.61 | 19.71 ± 10% |

| INFRACELL75-445 | 320 x 287 | 2.56 x 9.75 | 24.96 ± 10% |

| INFRACELL75-712 | 508 x 475 | 2.54 x 16.15 | 41.02 ± 10% |

| INFRACELL100-356 | 259 x 224 | 2.59 x 7.61 | 19.71 ± 10% |

| INFRACELL100-445 | 320 x 287 | 2.56 x 9.75 | 24.96 ± 10% |

| INFRACELL100-712 | 508 x 475 | 2.54 x 16.15 | 41.02 ± 10% |

| INFRACELL150-356 | 259 x 224 | 2.59 x 7.61 | 19.71 ± 10% |

| INFRACELL150-445 | 320 x 287 | 2.56 x 9.75 | 24.96 ± 10% |

| INFRACELL150-712 | 508 x 475 | 2.54 x 16.15 | 41.02 ± 10% |

| INFRACELL200-356 | 259 x 224 | 2.59 x 7.61 | 19.71 ± 10% |

| INFRACELL200-445 | 320 x 287 | 2.56 x 9.75 | 24.96 ± 10% |

| INFRACELL200-712 | 508 x 475 | 2.54 x 16.15 | 41.02 ± 10% |

| INFRACELL300-712 | 508 x 475 | 2.54 x 11.40 | 28.95 ± 10% |

Infracell100 Series Technical Specifications

| Index Properties | Test Method | Unit | 100-356 | 100-445 | 100-712 |

|---|---|---|---|---|---|

| Polymer | – | – | HDPE | HDPE | HDPE |

| Carbon Black content | ASTM D 1603 | % | ≥1.5 | ≥1.5 | ≥1.5 |

| Density | ASTM D 1505 | g/cm3 | ≥0.94 | ≥0.94 | ≥0.94 |

| Sheet Thickness | ASTM D 5199 | mm | 1.50 | 1.50 | 1.50 |

| Seam Peel Strength | – | N | 1600 | 1600 | 1600 |

| Weld Spacing | – | mm | 356 | 445 | 712 |

| Cell Depth | – | mm | 100 | 100 | 100 |

| Dimensions | |||||

|---|---|---|---|---|---|

| Expanded Cell Size (width x length) | – | mm | 259 x 224 | 320 x 287 | 508 x 475 |

| Expanded Panel Size (width x length) | – | m | 2.59 x 7.61 | 2.56 x 9.75 | 2.54 x 16.15 |

| Expanded Cell Area | – | m2 | 19.71 ± 10% | 24.96 ± 10% | 41.02 ± 10% |

Application Guidance

| Cell Depth | Gross Vehicle Weight | Application |

|---|---|---|

| 75mm | <1,000 kgs | Pedestrians (with cyclist) path |

| 100mm | <3,000 kgs | Domestic Traffic: Cars |

| 100-150mm | <6,000 kgs | Car Park: Cars & Light Van |

| <9,000 kgs | Delivery Vans | |

| 150mm | <16,000 kgs | Emergency Access & Tractors |

| 150-200mm | <30,000 kgs | Standard Construction Traffic & Refuse Vehicle |

| 200mm | <50,000 kgs | Heavy Construction Traffic |

| 200mm | <60,000 kgs | HGV & Unusual – Crane / Piling Rig |