Biaxial Polypropylene Geogrids for soil reinforcement

Rigid biaxial geogrids improve the performance of aggregate base course materials supporting paved and unpaved roadway surfaces, railway ballast and Mechanically Stabilised Earth (MSE) walls and slopes. Their integrally formed structure provides lateral stability of unbounded base courses by the interlocking of granular particles into the geogrid apertures, thus improving their vertical stress distribution characteristics. The reinforcement action of polypropylene geogrids is generated by the vertical stress causing both the aggregate and geogrid to deform. Roads and railways built with PP biaxial geogrids have increased load bearing capacity, a longer service life and reduced section thickness.

Our biaxial geogrids are manufactured by extruding, punching, longitudinal and transverse stretching of polypropylene. This results in a geogrid with high flexural rigidity and high tensile modulus in both the longitudinal (MD) and transverse (TD) directions. Because polypropylene geogrids have excellent structural stability and strong mechanical interlock performance they are ideal for soil reinforcement.

The performance of unsealed and sealed roads is critically dependent on materials used. Research by the US Corps of Engineers has shown aggregate layers stabilised with PP geogrids deliver significant performance benefits to flexible road pavements and reduce surface rutting by up to 44% compared with non-stabilised aggregate. Incorporating geogrid into a road pavement could cut construction time and costs by up to 19% and delay the onset of pavement failure by controlling lateral and vertical displacement of aggregates from traffic loads. Geogrids also help to overcome shortages of quality quarried materials and natural gravels used for road construction.

Biaxial Geogrid Applications

- Base reinforcement – reduced lateral spreading of the base course

- Subgrade reinforcement – increased confinement leading to stiffer base

- Slope reinforcement

- Road pavements

- Mechanically Stabilised Earth embankment stabilization

Biaxial polypropylene geogrids are available with the following tensile strengths:

15/15kN/m 20/20kN/m 25/25kN/m 30/30kN/m 40/40kN/m 45/45kN/m 50/50kN/m

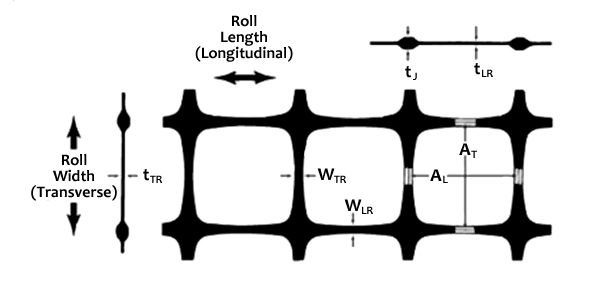

Structure of a composite biaxial geogrid

Specifications

| Product | AL | AT | WLR | WTR | tLR | tTR | tJ |

|---|---|---|---|---|---|---|---|

| INFRAGRID1515 | 36 | 36 | 2.6 | 2.6 | 1.0 | 0.8 | 3.1 |

| INFRAGRID2020 | 35 | 35 | 2.6 | 2.6 | 1.5 | 1.1 | 3.5 |

| INFRAGRID2525 | 34 | 34 | 2.8 | 2.8 | 1.8 | 1.4 | 4.2 |

| INFRAGRID3030 | 34 | 34 | 3.0 | 3.0 | 2.5 | 1.5 | 4.9 |

| INFRAGRID4040 | 33 | 33 | 3.0 | 3.0 | 3.4 | 2.1 | 5.5 |

| INFRAGRID4545 | 32 | 32 | 3.1 | 3.1 | 4.1 | 2.2 | 5.6 |

| INFRAGRID5050 | 30 | 30 | 3.1 | 3.1 | 4.3 | 2.5 | 5.8 |

*unit=mm

Biaxial PP Geogrid INFRAGRID2020

| Index Properties | Test Method | Units | MD Values | TD Values |

|---|---|---|---|---|

| Polymer | – | – | PP | – |

| Minimum Carbon Black | ASTM D 4218 | % | 2 | – |

| Tensile Strength @ 2% Strain | ASTM D 6637 | kN/m(lb/ft) | 7(480) | 7(480) |

| Tensile Strength @ 5% Strain | ASTM D 6637 | kN/m(lb/ft) | 14(960) | 14(960) |

| Ultimate Tensile Strength | ASTM D 6637 | kN/m(lb/ft) | 20(1,370) | 20(1,370) |

| Strain @ Ultimate Strength | ASTM D 6637 | % | 13 | 13 |

| Structural Integrity | ||||

|---|---|---|---|---|

| Junction Efficiency | GRI GG2 | % | 93 | 93 |

| Flexural Rigidity | ASTM D 7748 | mg-cm | 750,000 | – |

| Aperture Stability | COE Method | m-N/deg | 0.50 | – |

| Dimensions | ||||

|---|---|---|---|---|

| Aperture Dimensions | – | mm(in) | 35(1.4) | 35(1.4) |

| Minimum Rib Thickness | ASTM D 1777 | mm(in) | 1.5(0.06) | 1.1(0.04) |

| Roll Width | – | m(ft) | 3.95(12.9) or 5.95(19.5) | – |

| Roll Length | – | m(ft) | 50(164) | – |

How Betzoid Examines La Liga Match Outcome Patterns Over Time

Spain’s top football division has long captivated audiences with its technical brilliance, tactical sophistication, and unpredictable narratives. Understanding how match outcomes evolve across seasons requires systematic analysis that goes beyond surface-level statistics. Betzoid has developed comprehensive methodologies to examine La Liga’s complex patterns, tracking everything from home advantage fluctuations to the impact of managerial changes on team performance. By analyzing historical data spanning multiple decades, these examination techniques reveal underlying trends that shape competitive dynamics in one of Europe’s most prestigious leagues.

Historical Data Collection and Pattern Recognition Methodology

Betzoid’s approach to examining La Liga match outcomes begins with extensive historical data aggregation, collecting information from every season since the league’s modern era began. This database encompasses not merely final scores, but contextual factors including squad rotations, injury reports, referee assignments, weather conditions, and fixture congestion periods. The platform employs statistical models that identify recurring patterns across different time frames, from short-term momentum shifts to long-term cyclical trends that emerge over multiple seasons.

The examination process distinguishes between various outcome categories, analyzing wins, draws, and defeats through multiple lenses. Home and away performance metrics receive separate treatment, recognizing that venue advantage has fluctuated significantly throughout La Liga’s history. During the 1990s and early 2000s, home teams won approximately 48-52% of matches, but this advantage has gradually diminished in recent years as tactical evolution and improved travel conditions have leveled the playing field. Betzoid’s temporal analysis tracks these shifts quarter by quarter, revealing how competitive balance changes within individual seasons.

Pattern recognition algorithms identify anomalies that signal potential turning points in team trajectories. For instance, when a traditionally defensive side suddenly produces high-scoring matches, or when a dominant team begins drawing matches they previously won comfortably, these deviations often precede larger strategic shifts. The examination methodology also accounts for opponent quality adjustments, ensuring that a victory against Barcelona carries different analytical weight than a win over a newly promoted side.

Seasonal Trends and Competitive Cycle Analysis

La Liga exhibits distinct seasonal patterns that Betzoid’s examination framework carefully documents. The opening months of each campaign typically feature higher unpredictability as teams integrate new signings and managers implement tactical adjustments. Historical data shows that approximately 35% of eventual season-ending positions are established by matchday ten, with the remaining 65% still subject to significant movement. This volatility creates specific windows where outcome patterns deviate from long-term averages.

Mid-season periods, particularly January through March, demonstrate different characteristics. Teams competing in European competitions often experience performance dips in domestic fixtures due to squad rotation and accumulated fatigue. Betzoid’s analysis reveals that clubs participating in Champions League knockout stages win approximately 8-12% fewer La Liga matches during these months compared to their season averages. Conversely, teams eliminated from cup competitions frequently experience performance surges as they concentrate resources on league positioning.

The examination of outcome patterns also considers how competitive cycles operate across multiple seasons. La Liga has historically experienced periods of concentrated dominance, such as Barcelona’s 2008-2012 era or Real Madrid’s late 1980s supremacy, followed by phases of greater competitive balance. Those seeking deeper insights into these evolving dynamics can explore comprehensive La Liga betting tips that incorporate both historical patterns and current form indicators. Understanding these macro-level cycles helps contextualize individual match outcomes within broader competitive narratives.

End-of-season dynamics present another distinct pattern category. Teams with nothing to play for often produce unexpected results, while those fighting relegation or competing for European qualification demonstrate statistically significant performance improvements. Betzoid’s data indicates that teams in the bottom three positions with five matches remaining win approximately 22% more points per game than their season averages, reflecting heightened motivation and tactical desperation.

Tactical Evolution and Its Impact on Match Outcomes

The tactical landscape of La Liga has transformed dramatically over the past three decades, and Betzoid’s examination methodology tracks how these changes influence match outcome distributions. The league’s traditional emphasis on technical skill and possession-based football has evolved to incorporate diverse tactical approaches, from high-pressing systems to defensive counter-attacking strategies. Each tactical trend produces distinctive outcome patterns that become visible through longitudinal analysis.

The introduction of advanced metrics has revolutionized how outcome patterns are understood. Expected goals (xG) data, when analyzed historically, reveals that La Liga teams have become increasingly efficient at converting chances, with the gap between xG and actual goals narrowing by approximately 15% over the past decade. This efficiency improvement affects draw frequencies, as teams are less likely to squander dominant performances. Betzoid incorporates these metrics into temporal analyses, examining how tactical innovations influence the relationship between process and results.

Managerial influence represents another critical factor in outcome pattern analysis. When high-profile managers arrive at La Liga clubs, Betzoid’s examination tracks performance changes across multiple dimensions. Data shows that new managers experience an average “bounce” lasting approximately seven matches, during which win percentages increase by 18-25% compared to their predecessor’s final ten games. However, this effect varies significantly based on the manager’s tactical philosophy alignment with existing squad characteristics.

Set-piece effectiveness has also evolved considerably, with La Liga teams scoring from dead-ball situations at rates 30% higher in 2020-2024 compared to 2000-2004. This tactical development has particularly impacted outcomes in matches between mismatched opponents, where set pieces provide pathways for underdogs to secure unexpected results. Betzoid’s pattern examination specifically tracks these specialized situations, recognizing their growing influence on overall outcome distributions.

Advanced Statistical Models and Predictive Framework Development

Betzoid employs sophisticated statistical models that extend beyond simple historical frequency analysis. Machine learning algorithms process multidimensional datasets to identify non-obvious correlations between variables that traditional analysis might overlook. These models account for factors including squad depth metrics, recent transfer activity impact, and even psychological elements such as derby match intensity or revenge motivation following previous defeats.

The examination framework incorporates regression analysis to determine which historical patterns maintain predictive validity versus those that represent statistical noise. For example, the “curse of the early leader” – where teams topping the table after ten matches historically underperform expectations – has diminished in recent seasons as squad depth has improved across top clubs. Betzoid’s models weight historical patterns according to their contemporary relevance, ensuring that outdated trends don’t distort current analysis.

Temporal weighting represents another sophisticated element of the examination methodology. Recent seasons receive greater analytical emphasis than distant historical data, but not uniformly so. The weighting system accounts for structural changes in La Liga, such as the 1995 Bosman ruling’s impact on squad composition or the 2015 collective television rights deal that improved competitive balance. By contextualizing historical patterns within these structural frameworks, Betzoid’s analysis maintains relevance while preserving valuable long-term insights.

The platform also examines outcome patterns through Bayesian probability frameworks, which update predictions as new information emerges throughout each season. This dynamic approach recognizes that match outcome probabilities are not static but evolve based on accumulating evidence. A team’s underlying performance metrics might suggest future improvement even during a poor results period, and Betzoid’s examination methodology identifies these discrepancies between short-term outcomes and longer-term trajectories.

Understanding La Liga’s match outcome patterns requires sophisticated analysis that balances historical perspective with contemporary context. Betzoid’s examination methodology demonstrates that successful pattern recognition extends far beyond simple win-loss records, incorporating tactical evolution, competitive cycles, and multidimensional statistical modeling. As the league continues evolving, these analytical frameworks adapt accordingly, providing insights that reflect both enduring competitive principles and emerging trends. The patterns revealed through systematic examination offer valuable understanding of how Spain’s premier football competition operates across time, highlighting the complex interplay between consistency and change that defines elite sporting competition.