Our InfraSheet series of Filter Sheet Drains provide a cost effective option to the conventional use of aggregate where large surface areas require drainage. Geosynthetics Australia’s dimpled plastic sheet drains provide effective drainage and waterproof membrane protection on foundation walls and other underground structures. They are widely used for vertical or horizontal drainage on piled structures, retaining walls, tunnel drainage, cavity drains, podium decks and soil bank stabilization. They alleviate the hydrostatic pressure behind walls and the potential for structural failure.

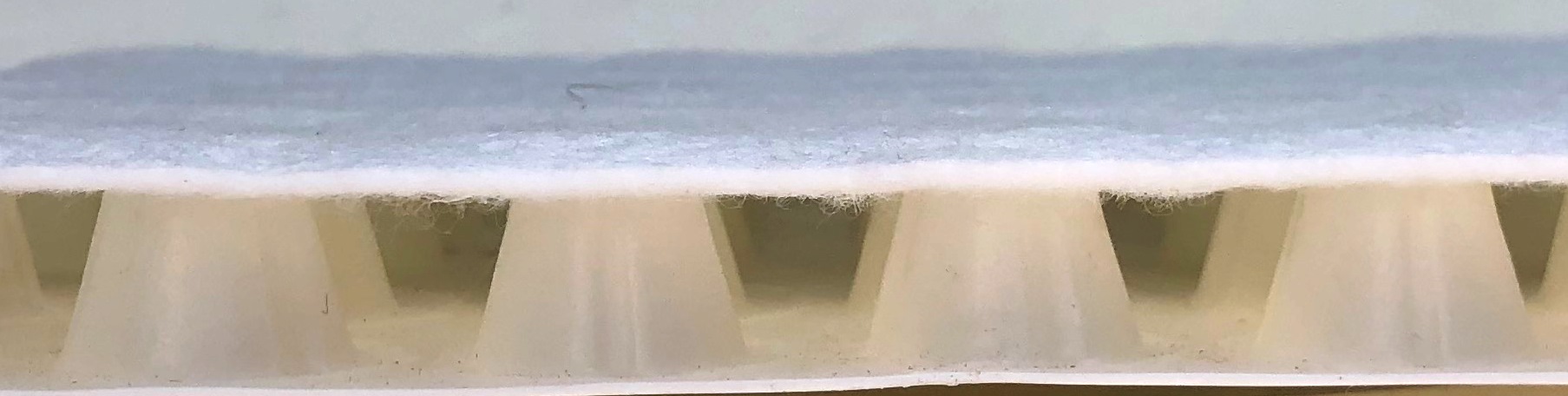

Single cuspated HDPE sheet drain with geotextile filter fabric

Filter fabric sheet drains are a composite geosynthetic made from a high quality, abrasion resistant, non-woven polyester geotextile filter fabric that is bonded to an impermeable HDPE cuspated core. Both polymers are inert to a wide range of acids and alkalis common in a soil environment.

Retaining Wall Drainage

Almost 80 percent of retaining walls fail at some point due to improper drainage. To avoid this an effective drainage system should be installed behind the structure. Whilst it can be difficult to accurately calculate seepage through non homogeneous soils, GA sheet drains ensure that the permittivity into the core and the in-plane flow rate remain constant. Dimple sheet drains deliver superior drainage to traditional materials such as crushed aggregate and conventional pipe systems. Moreover they are lightweight, easy to handle and install, require minimal trench excavation and resist loads from infill and formwork.

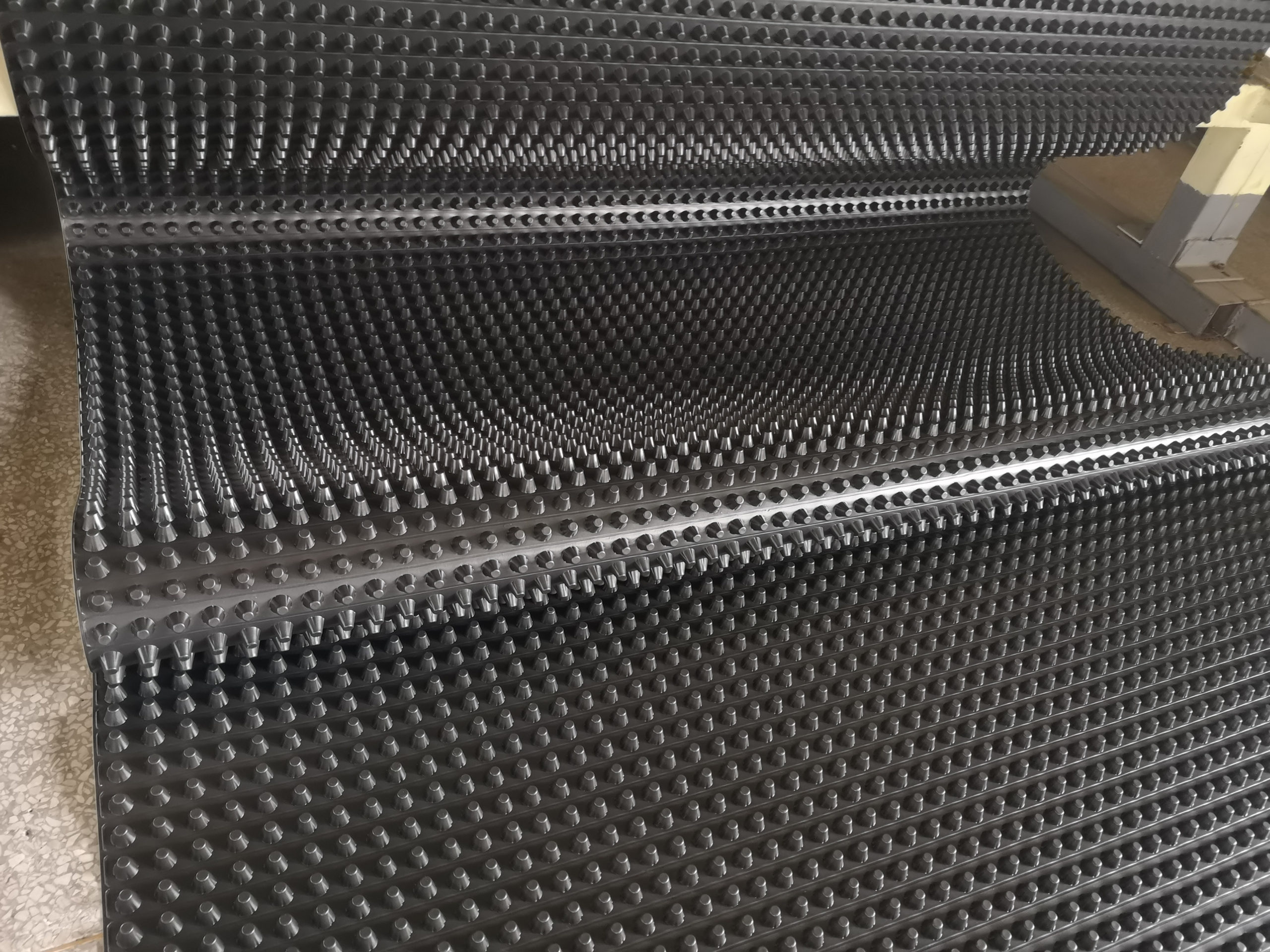

Filter sheet drain manufacture line

Geocomposite drains are installed with the geotextile facing the soil and the HDPE sheet up against the wall. The geotextile fabric prevents soil or sand particles from entering the three dimensional dimpled core and creates an air gap so that the wall can breathe and seepage condensates outward onto the plastic membrane. The moisture then falls to a footing drain where it is removed. The air gap helps to keep cement block walls dry and mould and fungi from growing on the wall.

Because of their high compressive strength, geocomposite sheet drains can be cast into the final concrete face or alternatively sprayed concrete can be applied on the surface to create the final finish. The HDPE cuspated drainage core provides an excellent bond with shotcrete. Filter fabric sheet drains can also be used as replacement for a no-fines concrete layer.

The prefabricated drainage system provides 3 primary benefits:

- Quickly removes water from behind retaining walls, relieving hydrostatic head pressure

- Provides a channel to take the water down to the collection system

- Protects the waterproofing, especially during backfilling

Waterproofing Membrane Protection

GA Geocomposite Sheet Drains also protect waterproofing material for both horizontal and vertical tanking applications. This eliminates the cost of a separate protection board. During backfilling or landscaping the stiff plastic sheet protects waterproofing membranes from sharp stones, traffic from on-site workers and tools from construction trades. Cuspated Sheet Drains also act as a thermal insulation barrier adjacent to the waterproofing membrane. They can be applied to concrete block work and highly textured surfaces.

Using sheet drains to protect waterproofing membrane in a railway tunnel

Road and Rail Tunnel Drainage

Because of the variation in permeability and grain size, the velocity of seeping water through porous media varies greatly (Darcy’s Law). GA Geocomposite Sheet Drain is designed to collect and drain large volumes of unwanted surface and groundwater from road and rail tunnels. Its high strength withstands ground pressures and the compaction forces of wet concrete. When connected to a tunnel drainage discharge system GA Sheet Drain maintains a high water flow and eliminates hydrostatic build-up against the structure.

The GA Filter Sheet Drain also protects the waterproofing membrane from damage. The dimpled drainage core creates an air void to isolate the structure from the effects of the surrounding ground.

Invert Cavity Drain

TD30 invert cavity sheet drain is a preformed geocomposite drainage system designed to relieve water penetration from tunnels, basements and buried structures. It can be used on both new and existing structures.

TD30 invert cavity drainage mat is made from High Density Polypropylene (HDPE). The open flow channels in the cuspated core deliver high flow velocities (up to 500L/min/m), which, together with the smooth surface, make geocomposite sheet drains extremely resistant to clogging by precipitates.

Tunnel Drainage

TD30 invert cavity protect and enhance the integrity of road or rail tunnels. Cavity drains relieve the effects of water penetration from tunnels and can be used in both tunnel walls and tunnel invert drainage. The flexible sheets follow the contours of excavated tunnel walls.

Invert cavity drains attach easily to the excavated wall of tunnels or onto a shotcrete smoothing layer with rondels. When shotcrete is applied, it adheres directly to the inverted surface of the liner with significantly less rebound loss than for smooth waterproof membranes.

TD30 provides a free draining void behind tunnel waterproofing and walls. The drainage layer collects infiltration water from the tunnel wall, reduces hydrostatic pressure and enhances the effectiveness of the waterproofing layer. TD30 replaces both the invert trench and piping normally used to collect water from the tunnel invert.

Basement Drainage

TD30 invert cavity drain relieves water penetration from basements and buried structures under reinforced concrete slabs. TD30 cavity drain’s in-plane water flow capacity is far in excess of crushed stone.

Installation is fast and cost effective as excavation and material movement is significantly reduced. When the dimples are laid face-down and a cement grout is poured on top they provide a pre-formed drainage layer into which the concrete floor slab can be cast. The high strength core is designed to withstand the compressive loads arising from placing wet concrete. Once the cement grout fills the dimples the drain achieves the ultimate load capacity of the concrete. TD30 can also be used as an effective gas collection barrier.

Core Properties

| Product | Material | Weight (g/ m2) | Thickness (mm) | Drainage Capacity (L/m2) | Transmissivity (L/min/m) | Compressive strength (kPa) | Dimensions* (MM) |

|---|---|---|---|---|---|---|---|

| TD-30 | High Density Polypropylene (HDPE) | 1500 | 30 | 7.0 | 500 | 150 | 2400×1000 |

*..includes 10cm wide flat along both edges * Including 10cm wide flat along both edges.

Geotextile Filter Fabric (when supplied)

| Material | Colour | Vertical Permeability Coefficient (cm/s) | EOS (O95) (mm) | CBR (KN) | Tear Strength (KN) | Tensile strength (KN/m) | Weight (g/m2) |

|---|---|---|---|---|---|---|---|

| Needlepunched monofilament polyester | White | 2.36 x 10-1 | 0.108 | 1.7 | 0.26 | 8.5 | 180 |